Project Execution

Project Execution

Project Management

Project planning is our first thing to consider in all projects. The plan will include a blueprint of the whole schedules and budget. Thai Herrick’s project management team has experience in managing and planning all structural steels as follows the customer’s requirements.

Our project management team is essential to monitor the project’s progress at every step closely. This includes understanding each task’s status and the resources being used as weekly basic. They can identify potential problems by analyzing the project’s progress and taking corrective action.

Purchasing

The procurement team uses the Bill of Material (BOM) to float inquiries to suppliers. Depending on the length, the steel structure is either cut to size or conventional length at competitive prices. The steel is either delivered to the manufacturing facility or sub-fabricators.

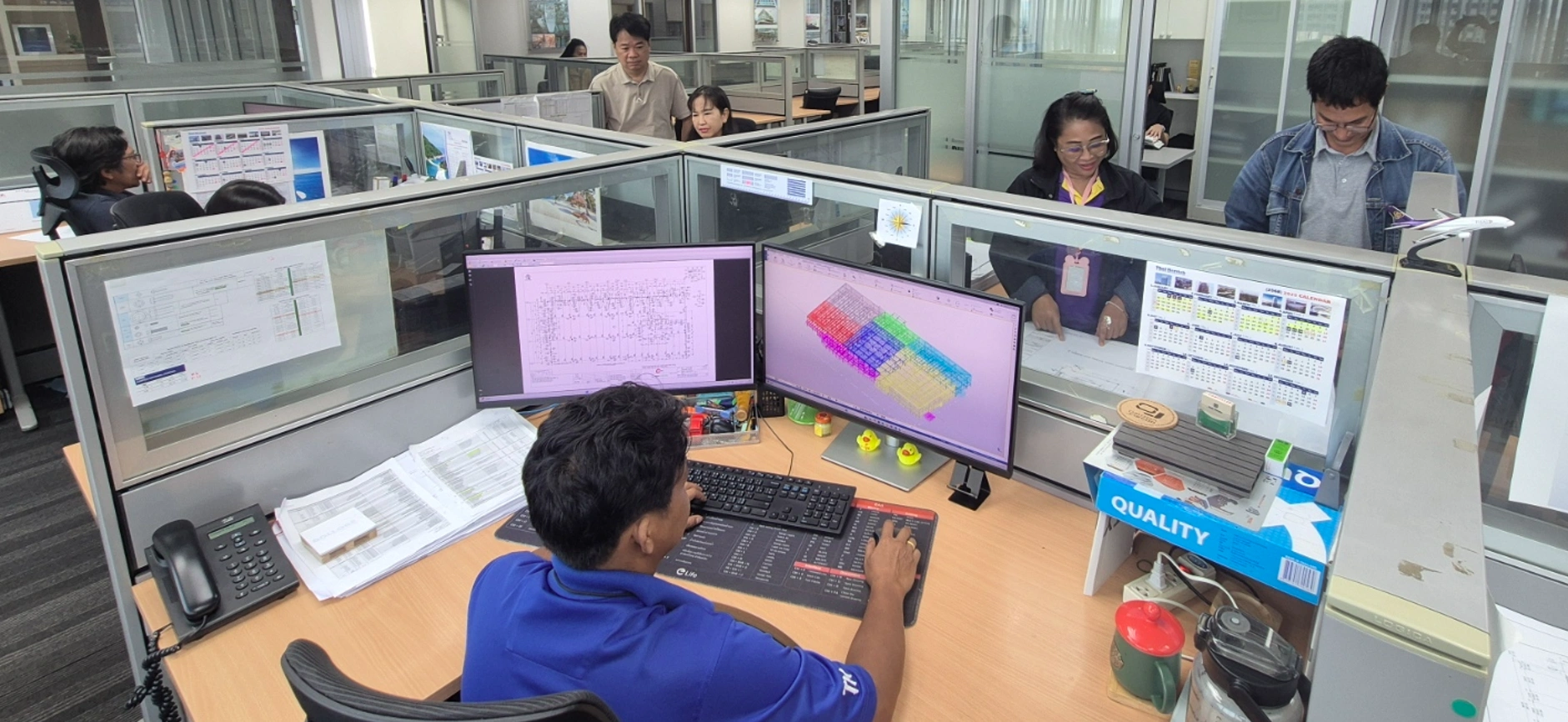

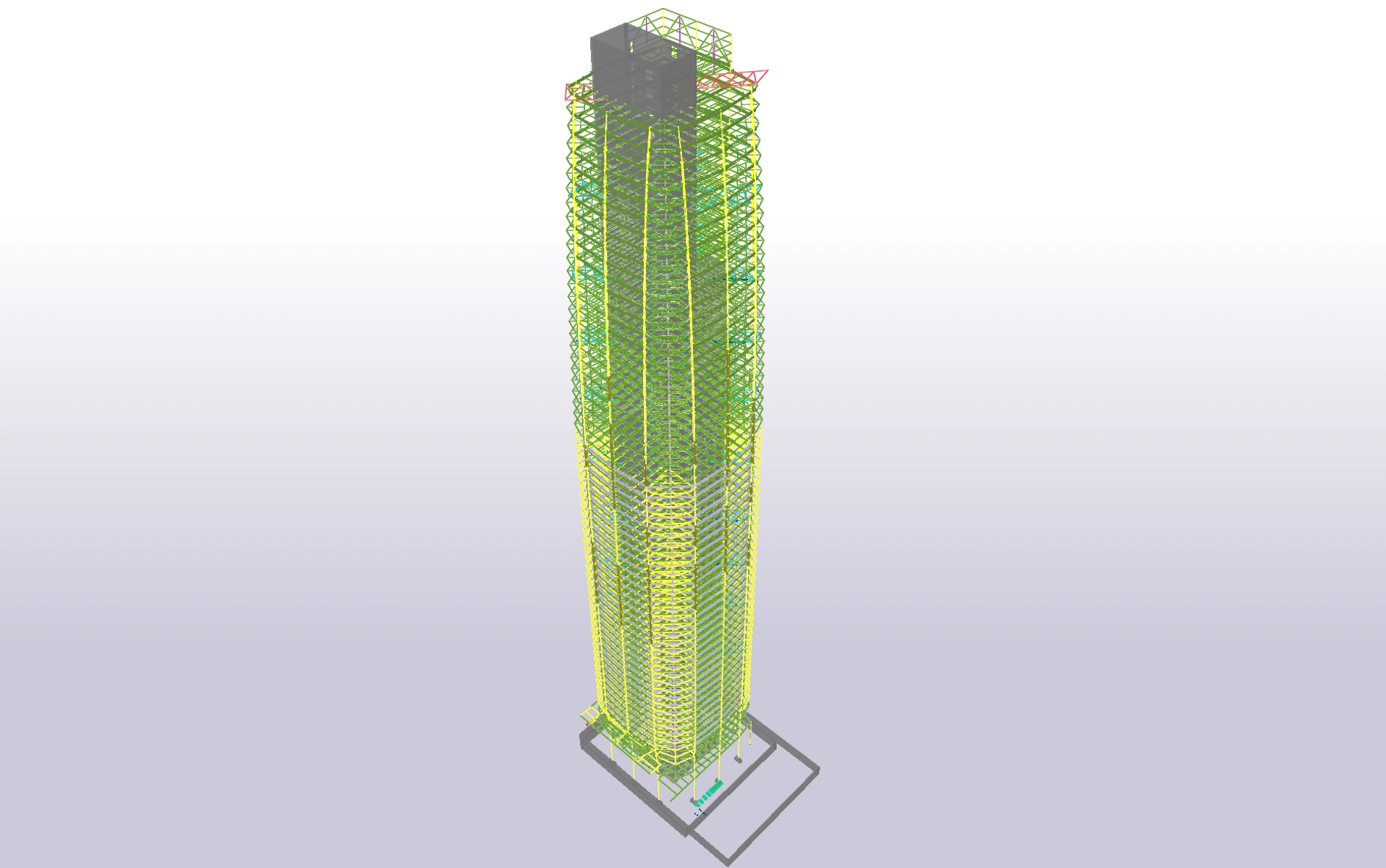

Engineering

It is a first step in our fabrication process that is detailing preparation. Customer sends project designs and specifications at this stage. The draftsman can now create 3D modeling from Tekla software then generates the Bill of Materials (BOM) and Bill of Quantities (BOQ) to provide the data required for procurement and production.

- Receive structural designs

- Review project specifications

- Generate 3D modeling and 2D shop drawings

- Material Lists and Reports for procurement

- Quality checks 2D shop drawings

- Issue for Review and Approval (IFA) by customer

- After customer approves the 2D shop drawings, then converts all the shop drawings in Issue for Fabrication (IFF) stage

- They also prepare CNC data files for automatic machines, fitting details, cutting plans and cutting lists as fabrication package (Fab –pack) for the shop

Engineering also provides ongoing support to the erection team by addressing any queries or issues that may arise during the erection of the steel structure on site.

Fabrication shop

Sub-assembly of the structure such as beams, columns and trusses are prefabricated in smaller sections in beam line and part workshop by automatic machines before assembly begins at assembly shop.

- Two beam lines are three equipment from Saw cutting, Drilling & Thermal coping machines for H-Shapes

- Angle & Plate are cutting/drilling in the part shop

- Built-up H-shape and Built-up BOX section are pre-assembled then move to Tandam machine for fully auto welding

- Light fabrication shop reserves for miscellaneous steels

The bar code system uses for tracking material status throughout processes (Fabrication, Coating, Packing, Shipping and Receiving at the end destination). Standard white barcode uses for labeling the products. It contains with P.O. number, Piece mark number, Job number, Weight, etc.

We can also supply barcode as multi colors for separate tracking in Material details, Shipment numbers or Erection sequences.

Quality Control and Finishing

After welding is completed, we perform quality checks to ensure the products meet all the requirements on shop drawings. This includes mechanical testing, dimensional inspections, visual inspections and non-destructive testing (NDT) to check for hidden defects and cracks.

Once the structure passes quality inspection, the structural steel surfaces require protective coatings in order to avoid corrosion and prolong its longevity, such as paint, epoxy or galvanization. After that, the components are now ready for packing and shipping.

Transportation control

Logistics essential planning ahead when transporting prefabricated steel components to the port or site, especially large structures which may need special transportation and handling equipment. We also aware of safety that must always come first when transporting steel components through the public roads. Then fabricated steel components carefully packed to prevent damage throughout all delivery processes.

Safety Achievement

The safety of the workers is also a crucial aspect to consider during our fabrication process. We have a strict policy on maintaining a safe work environment for all employees.